Testing and tagging electrical equipment in Sydney is a legal necessity to reduce workplace incidents and maintain compliance with AS/NZS 3760:2022 and NSW WHS legislation. This guide reveals exactly how often you should test and tag in different environments, explains regulatory obligations under the WHS Act 2011 NSW and SafeWork NSW guidelines, and outlines risk-based adjustments. You’ll learn:

- The core legal requirements and standards for test and tag in NSW

- Environment-specific retest intervals from construction sites to offices

- Qualifications for competent persons and in-house versus outsourced testing

- How risk assessments and RCD protocols influence frequencies

- Best practices for record keeping, audit readiness and insurance support

Whether you oversee a construction project, warehouse operations or office facilities, this resource ensures you meet “test and tag requirements NSW” with confidence.

What Are the Legal Requirements for Test and Tag in NSW?

Under NSW law, businesses must ensure portable and fixed electrical equipment is regularly inspected, tested and tagged to confirm it remains safe for use. Compliance hinges on aligning practices with the AS/NZS 3760:2022 standard and the WHS Act 2011 NSW framework, enforced by SafeWork NSW.

Legal Requirements for Test and Tag in NSW

Businesses in NSW are legally obligated to ensure that their electrical equipment undergoes regular inspection, testing, and tagging to maintain safety. This is in accordance with the AS/NZS 3760:2022 standard and the WHS Act 2011 NSW, which are enforced by SafeWork NSW.

What Does the AS/NZS 3760:2022 Standard Specify About Test and Tag Frequency?

AS/NZS 3760:2022 defines inspection and testing protocols for electrical appliances, requiring visual inspection, earth continuity, insulation resistance and functional tests at prescribed intervals. For example, power tools must undergo earth continuity tests every six months in low-risk settings, while extension leads demand quarterly retests in harsh environments. These procedures establish a baseline safety mechanism that underpins all NSW test and tag schedules.

How Does the Work Health and Safety (WHS) Act 2011 NSW Affect Test and Tag Obligations?

The WHS Act 2011 mandates that duty holders eliminate or minimise electrical hazards. Under Section 19, businesses must maintain safe systems of work, which include regular electrical testing schedules. Failure to manage these risks can trigger enforcement notices and fines up to $3 million (AUD).

Embedding test and tag within your safety management system transforms compliance into proactive risk control.

What Role Does SafeWork NSW Play in Electrical Safety Compliance?

SafeWork NSW issues codes of practice and inspects workplaces to enforce WHS regulations. Its guidance clarifies acceptable testing methods, record-keeping requirements and definitions of a “competent person.” Audits by SafeWork NSW often reference AS/NZS 3760:2022, making adherence essential for audit readiness.

Aligning processes with SafeWork NSW guidance ensures your test and tag services withstand regulatory scrutiny.

What Are the Consequences of Failing to Comply with Test and Tag Regulations in Sydney?

- Prohibition or improvement notices from SafeWork NSW

- Significant financial penalties under the WHS Act

- Voided insurance policies if electrical faults cause incidents

- Increased risk of workplace injury and reputational damage

Understanding these legal and insurance-related stakes drives businesses to adopt robust test and tag regimes.

How Often Should Electrical Equipment Be Tested and Tagged in Different Sydney Environments?

Test and tag frequency varies by environment based on exposure to mechanical damage, moisture or chemical hazards. The following table summarises minimum intervals under AS/NZS 3760:2022 and AS/NZS 3760:2022.

| Environment | Testing Intervals | Relevant Standard |

|---|---|---|

| Construction & Demolition Sites | Every 3 months | AS/NZS 3760:2022 |

| Factories, Warehouses, Production | Every 6 months | AS/NZS 3760:2022 |

| Offices, Retail & Low-Risk Environments | Every 12 months | AS/NZS 3760:2022 |

| Server Rooms | Every 5 years | AS/NZS 3760:2022 |

What Are the Test and Tag Frequencies for Construction and Demolition Sites in Sydney?

Portable tools and extension cords on construction sites demand a three-monthly earth continuity and insulation resistance test due to high mechanical stress. AS/NZS 3760:2022 requires documented evidence of tester competence and detailed tagging.

Test and Tag Frequency in Construction

Construction sites in Sydney require a three-monthly testing and tagging schedule for portable tools and extension cords. This is due to the high mechanical stress and potential hazards present in these environments, as mandated by AS/NZS 3760:2022.

By adhering to these quarterly checks, construction managers preserve site safety under rigorous conditions.

How Often Should Factories, Warehouses, and Production Facilities Test and Tag Equipment?

In industrial settings, six-monthly visual inspections and electrical safety tests address wear from heavy machinery and dust exposure. Fixed wiring and portable appliances both fall under this interval, ensuring uninterrupted production and compliance. A biannual schedule balances operational efficiency with risk mitigation in manufacturing environments.

What Are the Testing Intervals for Offices, Retail, and Low-Risk Environments in NSW?

Equipment such as computers, printers and kettle leads in low-risk office contexts require annual testing. This 12-month baseline supports safe office operations without unnecessary downtime.

Who Can Perform Test and Tag Services in Sydney? Understanding Competent Person Requirements

A “competent person” under AS/NZS 3760:2022 possesses electrical testing qualifications, practical experience and formal training in appliance testing. Competence requires certification in portable appliance testing and knowledge of relevant standards.

What Qualifications Define a Competent Person for Test and Tag in NSW?

- A recognised electrical testing qualification

- Hands-on experience with portable appliance testers (PAT testers)

- Formal training on AS/NZS 3760:2022 procedures and WHS regulations

These credentials confirm the tester’s ability to identify faults and apply correct tagging methods.

How Can Businesses Find Qualified Test and Tag Professionals in Sydney?

Leading electrical test and tag providers list their qualifications, insurance coverage and compliance guarantees on service pages. Look for providers with:

- Accredited training certificates

- Public liability insurance

- Recent SafeWork NSW audit endorsements

Selecting a reputable service partner accelerates your path to regulatory alignment.

Can Businesses Perform In-House Test and Tag, and What Are the Compliance Considerations?

Organisations may train internal staff as competent persons, provided they complete accredited courses and maintain up-to-date equipment. In-house testing demands rigorous documentation, refresher training and impartial audits to validate ongoing compliance.

Balancing cost savings with administrative overhead guides the decision between in-house and outsourced testing.

How Does Risk Assessment Influence Test and Tag Frequency in Sydney Workplaces?

Risk assessments evaluate environmental hazards, equipment conditions and usage patterns to fine-tune retest intervals beyond minimum standards. A robust assessment identifies factors that increase electrical risk and prescribes more frequent checks.

What Is a Workplace Electrical Risk Assessment and How Is It Conducted?

- Identifying equipment types, usage frequency and environmental conditions

- Evaluating potential hazard sources (moisture, dust, mechanical stress)

- Assigning risk ratings that inform test intervals

This systematic process embeds dynamic safety controls within compliance protocols.

How Can Risk Assessments Lead to More Frequent Testing Than Minimum Standards?

If assessment outcomes reveal elevated risk (such as equipment exposed to chemicals or heavy vibration) organisations may adopt quarterly or monthly tests, surpassing AS/NZS 3760:2022 minima. These customised schedules prevent unplanned downtime and safeguard workers. Tailored frequencies ensure that high-risk assets receive the attention they require.

What Types of Hazards Affect Test and Tag Schedules in Different Environments?

- Mechanical impact or abrasion on power cords

- Corrosive agents in food processing or laboratory settings

- Ultraviolet exposure on outdoor sites

- Frequent relocation of portable appliances on hire or event equipment

What Are the Specific Test and Tag Requirements for Residual Current Devices (RCDs) in Sydney?

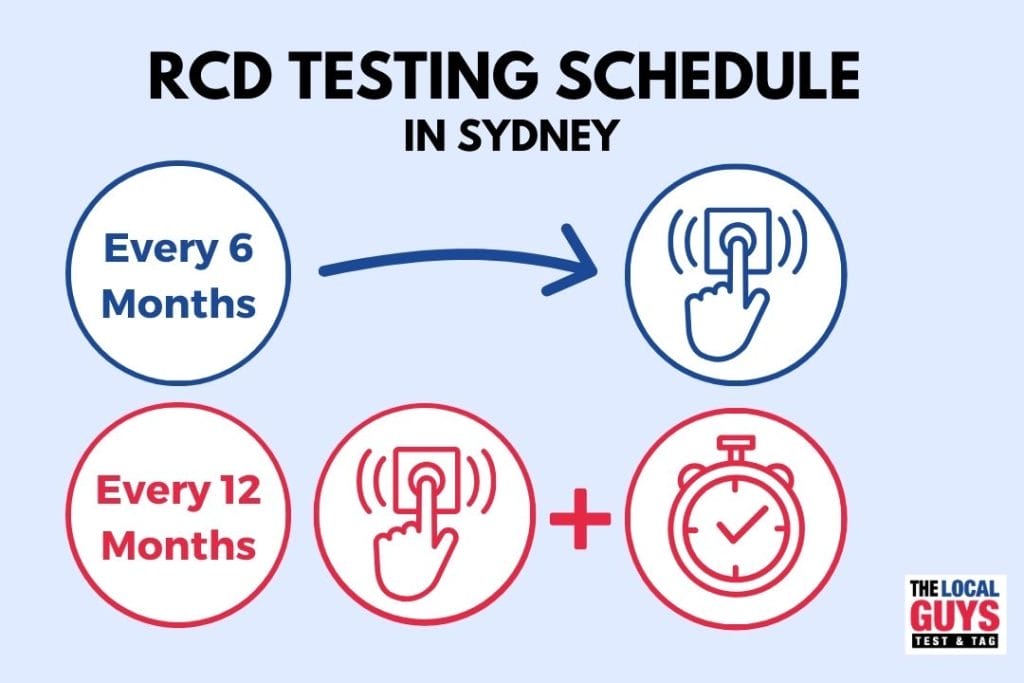

RCD testing protects against electric shock by verifying trip times and push-button operation. AS/NZS 3760:2022 mandates a push-button test and full operating time test at defined intervals.

How Often Should Portable and Fixed RCDs Be Tested and Tagged?

RCD Testing Requirements

Regular RCD safety switch testing is a critical component of electrical safety. RCDs require a push-button function test every 6 months and an operating time test every 12 months.

What Are the Safety Benefits of Regular RCD Testing in NSW Workplaces?

- Detects degraded trip sensitivity before failure

- Reduces shock risk to employees and visitors

- Supports compliance evidence for insurers and auditors

These benefits reinforce electrical hazard controls and underpin workplace safety.

How Should Sydney Businesses Maintain Records and Documentation for Test and Tag Compliance?

Legal record-keeping under NSW regulations requires retention of test certificates and tag logs for at least two years. Records must include test dates, equipment details, test results and competent person credentials.

What Are the Legal Record-Keeping Requirements for Test and Tag in NSW?

- Keep detailed test reports for all portable and fixed equipment

- Archive inspection certificates and tags with next test dates clearly marked

- Retain records in accessible formats for SafeWork NSW inspections

Meeting these requirements prevents enforcement action and insurance disputes.

What Are Best Practices for Organising and Storing Test and Tag Records?

- Digital databases with search, filter and export functions

- Secure cloud storage with backup and access controls

- Versioned audit trails to track data entry and amendments

Streamlined systems accelerate internal reviews and external audits.

How Do Proper Records Support Workplace Safety Audits and Insurance Claims?

- Demonstrates proactive electrical risk management

- Validates compliance during WHS audits

- Provides insurers with evidence of due diligence

Well-maintained records convert safety activities into tangible business value.

What Are the Benefits of Regular Test and Tag Services for Sydney Businesses?

Routine testing delivers safety and financial advantages by preventing equipment failures, reducing downtime and bolstering regulatory compliance. Proactive electrical inspections support a culture of risk management and workplace confidence.

How Does Test and Tag Minimise Electrical Risks for Employees and Visitors?

- Prevents electric shocks and fire hazards

- Reduces unplanned maintenance interruptions

- Elevates overall workplace safety standards

Early detection underpins a safer working environment.

Can Regular Testing Reduce Insurance Premiums and Liability Risks?

Insurance underwriters recognise documented electrical safety programs and may offer premium discounts. Clear test and tag records demonstrate risk control measures, lowering the likelihood of denied claims due to negligence.

How Does Professional Test and Tag Support Ongoing Regulatory Compliance?

Engaging accredited service providers ensures consistent application of AS/NZS 3760:2022 procedures, up-to-date test equipment and independent audit trails. Expert involvement minimises compliance gaps and frees internal teams to focus on core operations.

Where Can Sydney Businesses Find Reliable Test and Tag Services?

Selecting a trustworthy test and tag provider hinges on proven expertise, transparent methodologies and responsive support. Established services combine in-depth standards knowledge with local Sydney coverage.

What Should You Look for When Choosing a Test and Tag Provider in Sydney?

- Accreditation to AS/NZS 3760:2022 and WHS guidelines

- Full insurance coverage and safety record

- Clear reporting formats and documentation

- Automatic reminders for test and tag services

These criteria guarantee consistency and peace of mind.

Are There Local Sydney Suburbs or Districts with Specific Test and Tag Considerations?

Urban environments like the CBD may require more frequent testing of mobile devices due to high foot traffic, while coastal regions face corrosion risks from salt air. Industrial zones around Botany Bay demand strict adherence to harsh-environment protocols.

Book a Test and Tag Service Today

Are you due for testing and tagging in Sydney? Contact The Local Guys! You can get a free quote directly from our qualified technicians within 2 business hours.