Every year in Victoria, electrical faults contribute to a significant proportion of workplace incidents, making electrical appliance testing a critical safeguard for Melbourne businesses. Portable appliance testing Melbourne services inspect plug-in equipment for faults, ensuring compliance with AS/NZS 3760:2022 and preventing costly downtime or injury. In this guide, you will discover:

- What portable appliance testing is and why every Melbourne enterprise needs it

- The industries that benefit most from regular PAT inspections

- Key legal standards—AS/NZS 3760:2022, OHS Act 2004 and WorkSafe Victoria guidance

- The step-by-step PAT testing process and appliance test tag protocols

- How to select a competent provider and which appliances demand frequent testing

With expert insight into appliance test tag practices and regulatory frameworks, this article unifies safety requirements and practical steps for managers, compliance officers and facilities teams.

Electrical Safety in the Workplace

Electrical faults are a significant contributor to workplace incidents, highlighting the importance of regular appliance testing. Portable appliance testing (PAT) is a crucial safety measure for businesses, helping to prevent accidents and ensure compliance with safety standards.

What Is Portable Appliance Testing and Why Is It Essential for Melbourne Businesses?

Portable appliance testing (PAT) is the systematic inspection and electrical testing of plug-in equipment to detect insulation failures, earth continuity issues and wiring defects. By combining visual examination with targeted electrical measurements, PAT prevents electric shock and equipment malfunctions. For example, a Melbourne café that identified a faulty kettle cable during a routine PAT inspection avoided a fire risk and protected staff.

PAT testing ensures that every portable device—from power tools to kitchen appliances—meets Australian safety standards and contributes to a safe working environment. Understanding the scope of these tests clarifies their role in hazard prevention and compliance.

What Does Portable Appliance Testing Involve?

Portable appliance testing involves two core stages:

- Visual Inspection – A competent portable appliance tester examines plugs, cords and casings for wear, cracks or unauthorised modifications.

- Electrical Testing – Using a calibrated PAT tester, the technician will test:

- Earth Continuity to confirm safe grounding

- Insulation Resistance to check for leakage currents

- Polarity and Touch-Current for risk assessment

How Does PAT Testing Prevent Electrical Hazards and Workplace Accidents?

PAT testing neutralises three principal risk factors—faulty insulation, loose connections and compromised earth paths—by verifying electrical integrity and detecting hidden defects. When a tester measures insulation resistance above 1 MΩ, it confirms that current leakage cannot reach dangerous levels. This mechanism directly reduces the likelihood of electric shock incidents and fires, safeguarding staff and visitors while maintaining operational continuity.

What Are the Key Benefits of PAT Testing for Melbourne Industries?

PAT inspections deliver multiple advantages for businesses across sectors:

- Regulatory Compliance – Conforms with AS/NZS 3760:2022 and OHS duty of care

- Equipment Longevity – Early detection of wear extends device lifespan

- Insurance Validation – Demonstrates proactive risk management to underwriters

- Accident Prevention – Minimises electric shock, fire and trip hazards

- Cost Savings – Avoids downtime and repair costs through planned maintenance

Which Industries in Melbourne Require Portable Appliance Testing Most?

Melbourne’s diverse economy—from construction sites to corporate offices—relies on plug-in equipment that can pose serious electrical risks if unchecked. Identifying industry-specific hazards and testing frequencies ensures targeted safety measures.

Why Is PAT Testing Critical for the Construction Industry in Melbourne?

Construction sites deploy power tools, generators and extension leads in harsh environments where cables get pinched or exposed to moisture. AS/NZS 3760:2022 mandates electrical installations on construction and demolition sites, including regular inspections, but it does not explicitly mandate three-monthly PAT testing for all portable appliances. However, frequent inspections are recommended for high-risk equipment. A sturdy appliance test tag indicates that each tool passed earth continuity and insulation tests, reducing the risk of electrocution on site.

How Does Manufacturing and Industrial PAT Testing Reduce Risks?

Heavy machinery, 3-phase motors and workshop equipment undergo frequent use and vibration that can loosen connections. PAT inspections measure leakage currents and phase balance, preventing costly breakdowns and ensuring factory floors remain safe. Regular testing also verifies emergency stop circuits and safety interlocks.

What Are the PAT Testing Requirements for Office Environments?

In office settings, low-risk appliances such as computers, printers and coffee machines typically require annual to five-yearly inspections. A visual check catches cable damage under desks, while earth continuity tests confirm power boards and surge protectors won’t compromise employee safety. Tagging each device builds a maintenance log for audits.

How Does PAT Testing Protect Hospitality and Retail Businesses?

Restaurants, bars and retail outlets depend on kitchen equipment, POS terminals and display lighting. Frequent high-temperature cycles and customer foot traffic increase wear on cords and connectors. Quarterly or biannual inspections detect degraded insulation in kettles, ovens and EFTPOS machines, ensuring customer and staff safety.

Why Is PAT Testing Important in Healthcare and Education Sectors?

Hospitals and schools operate specialised appliances—infusion pumps, diagnostic equipment and lab instruments—that must function without failure. Annual or more frequent PAT cycles confirm that these critical devices maintain earth continuity and insulation integrity, supporting patient care and student safety.

What Are the Legal and Regulatory Requirements for PAT Testing in Melbourne?

Operating a safe workplace demands alignment with national standards and state regulations. Key frameworks establish the mandatory practices and frequencies for appliance testing in Melbourne.

What Is AS/NZS 3760:2022 and How Does It Govern PAT Testing?

AS/NZS 3760:2022 defines test methods, pass/fail criteria and inspection intervals. It classifies environments by risk level and specifies:

Australian Standards for Electrical Safety

AS/NZS 3760:2022 provides the framework for portable appliance testing, including test methods, pass/fail criteria, and inspection intervals. Adhering to this standard is considered best practice for fulfilling the duty of care to ensure a safe working environment.

| Environment | Inspection Frequency | Risk Level |

|---|---|---|

| Demolition / Construction Site | Every 3 months | Very high |

| Warehouse / Manufacturing Plant | Every 6 months | High |

| Office / School / Retail Store | Annually | Moderate |

| Server Rooms | Every 5 years | Low |

These intervals ensure systematic safety verification and clear visual cues via appliance test tags for next-due inspections.

How Does the Occupational Health and Safety Act 2004 Affect PAT Compliance?

The OHS Act 2004 places a duty of care on employers to eliminate or minimise risks. While it does not explicitly mandate PAT testing, adhering to AS/NZS 3760:2022 is widely recognised as best practice for fulfilling this obligation and defending against liability claims.

What Role Does WorkSafe Victoria Play in Electrical Safety?

WorkSafe Victoria issues guidance, conducts site inspections and enforces OHS regulations. Its safety alerts and approved codes encourage businesses to implement PAT programs, reinforcing electrical safety as a core component of workplace risk management.

How Often Must Different Appliances Be Tested According to Regulations?

| Appliance Type | Risk Category | Recommended Interval |

|---|---|---|

| Hand-held Power Tools | High-risk | Every 3 months (recommended) |

| Portable Heaters | Medium-risk | Every 6 months |

| Desktop Computers | Low-risk | Every 12 months |

| Medical Devices | Critical-use | Per manufacturer guidelines |

How Is the PAT Testing Process Conducted for Melbourne Businesses?

A systematic PAT testing process ensures that no step is overlooked, from initial inspection to final reporting.

What Are the Steps of Visual Inspection and Electrical Testing?

- Pre-test Assessment – Verify tester calibration and documentation readiness.

- Visual Examination – Inspect plugs, extension cords, casings and ventilation openings for damage or tampering.

- Earth Continuity Test – Measure earth resistance to confirm safe bonding.

- Insulation Resistance Test – Apply test voltage to detect leakage faults.

- Polarity and Touch-Current Test – Ensure correct wiring and assess leakage under normal use.

How Are Appliance Test Tags Used to Indicate Compliance?

Appliance test tags are durable labels affixed to each item, displaying:

- Test date and tester initials

- Next due date and frequency code

- Pass or fail status

What Documentation and Reporting Are Provided After Testing?

After each PAT cycle, businesses receive:

- A detailed compliance report with test results and observations

- A Certificate of Compliance

- A summary of failed items and repair recommendations

- A digital register of appliance test tag histories

How to Choose a Competent Portable Appliance Testing Provider in Melbourne?

Selecting the right service provider ensures reliability, accuracy and minimal disruption. By law, only a competent person may provide safety testing in Melbourne.

What Certifications and Experience Should a PAT Provider Have?

A qualified PAT tester should hold:

- AS/NZS 3760:2022 competency certification or equivalent training

- Electrical licence or equivalent vocational qualification

- Experience across relevant industries (construction, hospitality, healthcare)

Why Is Detailed Reporting and Insurance Important?

Comprehensive reporting verifies each test outcome, while public liability and professional indemnity insurance protect your business against any testing-related incidents. Transparency in findings and coverage details inspires trust.

How Can Businesses Ensure Minimal Disruption During Testing?

Plan testing during off-peak hours, provide clear access to equipment and communicate schedules in advance. A structured approach minimises downtime and maintains normal operations.

What Are the Most Common Appliances That Require Portable Appliance Testing in Melbourne?

Recognising which devices pose higher risks helps prioritise inspection schedules.

Which Electrical Appliances Are High Risk and Need Frequent Testing?

High-risk items include:

- Hand-held power tools and portable electrical appliances exposed to rough handling

- Portable heaters operating at high temperatures

- Extension leads used in harsh or wet conditions

How Are Office and Hospitality Appliances Categorised for Testing?

Office and hospitality devices range from:

- Computers, monitors and printers (annual to five-yearly intervals)

- Kettles, microwaves and refrigeration units (biannual to annual intervals)

- POS systems and kitchen blenders (quarterly to biannual intervals)

What Special Considerations Apply to Healthcare and Education Appliances?

Medical infusion pumps, diagnostic scanners and lab equipment demand precise calibration and strict adherence to manufacturer intervals, often on an annual cycle. In schools, laboratory hotplates and AV equipment also require careful testing to protect students and staff.

What Are Frequently Asked Questions About Portable Appliance Testing in Melbourne?

Below are clear explanations of common queries that support compliance and operational planning.

Is Test & Tag Legally Required in Victoria?

No, no statute explicitly mandates test and tag in Victoria. However, the OHS Act 2004 requires a safe workplace and AS/NZS 3760:2022 is regarded as best practice for meeting that legal duty of care.

How Often Should PAT Testing Be Conducted for Different Industries?

Testing intervals vary by risk: construction sites every three months (recommended for high-risk equipment), manufacturing plants every six months, and offices or retail environments annually, according to AS/NZS 3760:2022 classifications.

What Happens If Electrical Appliances Fail PAT Testing?

Failed appliances are tagged as unsafe and removed from service immediately. Repairs or replacements must occur before re-testing and re-tagging, ensuring no device returns to use with unresolved faults.

Can Businesses Perform PAT Testing Themselves or Use External Providers?

Internal staff may conduct PAT if they hold the necessary electrical qualifications and use calibrated equipment. Many businesses engage external specialists to guarantee impartiality, comprehensive reporting and full regulatory adherence.

Maintaining a robust PAT testing process protects Melbourne businesses from electrical hazards, compliance risks and operational disruptions. By understanding key standards, industry requirements and inspection frequencies, organisations can secure equipment integrity and safeguard people. Engaging a certified provider with AS/NZS 3760:2022 expertise and reliable documentation ensures every portable appliance remains safe, compliant and ready for service.

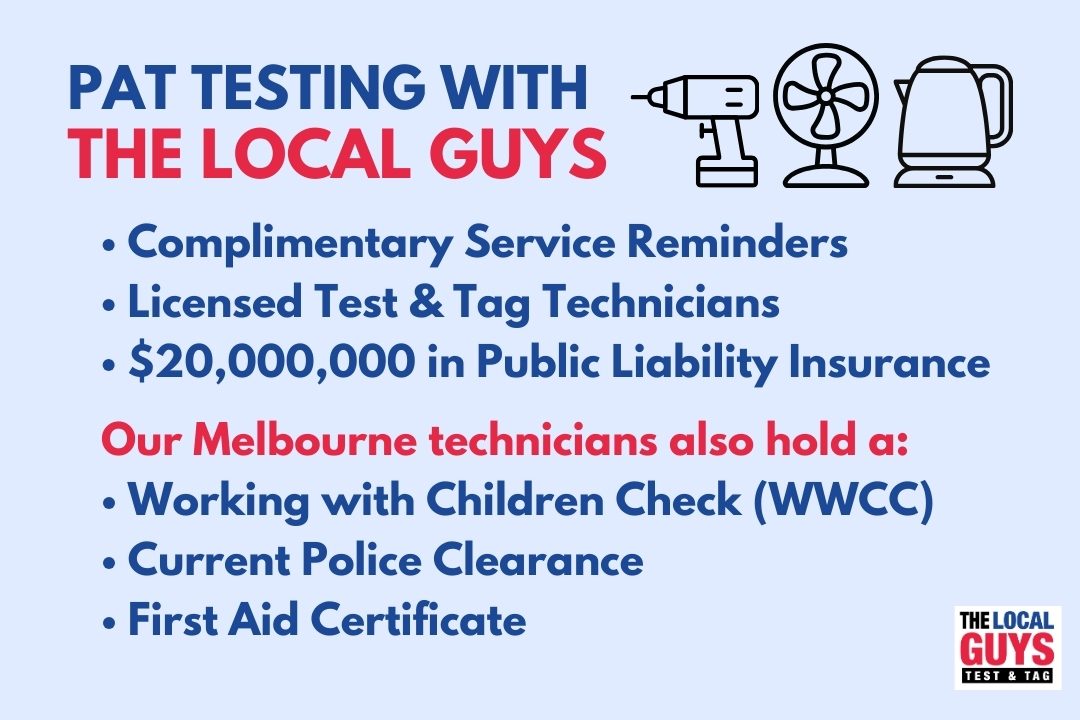

Book with The Local Guys Today!

Are you ready to book Portable Appliance Testing with The Local Guys? Our professional Test and Tag technicians are here to help with whatever testing and tagging services you need! Contact our Melbourne team today and get a free, no-obligation quote within 2 business hours.