Portable appliance testing, commonly known as appliance test and tag, is a legal and safety imperative across Adelaide workplaces to prevent electrical faults, injuries and downtime. Businesses that rely on portable electrical equipment face strict requirements under AS/NZS 3760:2022 and WHS Regulations 2012, making regular inspections non-negotiable.

AS/NZS 3760:2022 and Test and Tag Requirements

AS/NZS 3760:2022 outlines the procedures for the visual inspection, earth continuity, insulation resistance, and functional testing of portable appliances, specifying test intervals based on the environment and appliance type. This standard is a central requirement for businesses in Adelaide to ensure electrical safety and compliance.

This guide maps out which industries demand test and tag most frequently, the key standards driving compliance, the end-to-end testing process, the safety and cost benefits, provider selection criteria, typical pricing and scheduling, plus answers to common questions.

Which Adelaide Industries Require Test and Tag Services Most Frequently?

Construction, manufacturing, healthcare and hospitality sectors top the list for test and tag in Adelaide due to their diverse equipment and risk environments. These industries follow distinct inspection intervals to maintain electrical safety, manage insurance obligations and avoid penalties.

| Industry | Typical Frequency | Key Equipment |

|---|---|---|

| Construction & Demolition | Every 3 months | Power tools, extension leads, RCDs |

| Manufacturing & Production | Every 6 months | Machinery leads, workshop tools |

| Hospitality, Offices & Retail | Every 12 months | Kitchen appliances, POS terminals, computers, printers |

| Server Rooms | Every 5 years | Servers, routers |

These frequencies ensure equipment integrity and worker safety. Understanding specific intervals for each sector guides businesses towards tailored compliance plans.

What Are the Test and Tag Frequency Requirements for Construction and Demolition?

Construction and demolition sites involve harsh conditions that increase electrical hazards. Test and tag frequency in this sector is every three months to detect cable damage, dust ingress or moisture faults before they cause shocks or fire. For example, a drill cord fraying on a building site can be identified and replaced promptly. These rigorous intervals minimise downtime and uphold site safety before moving on to manufacturing environments.

Test and Tag Frequency for Construction Sites

Construction and demolition sites require test and tag inspections every three months due to the harsh conditions that increase electrical hazards. These rigorous intervals help to detect damage and prevent electrical shocks or fires.

How Often Do Manufacturing and Production Facilities Need Test and Tag?

Manufacturing plants feature continuous-run machinery that demands six-monthly inspections. For instance, a six-month inspection electrical equipment and tools can help avert production halts and repair costs while setting the stage for hospitality sector requirements.

What Are the Test and Tag Needs for Offices, Retail, and Hospitality Sectors?

Office, retail and hospitality environments use a wide range of low-risk appliances but still require annual inspections. Commercial kitchen appliances typically follow a 12-month schedule. A hospitality venue might test all countertop appliances yearly, ensuring guest safety and seamless service, which leads us to specialised high-risk industries.

What Are the Key Electrical Safety Regulations Governing Test and Tag in South Australia?

Adelaide businesses must comply with a framework of national standards and state regulations to remain legally operational and accident-free. Central requirements derive from AS/NZS 3760:2022, the model WHS Regulations 2012 for South Australia and site-specific standards like AS/NZS 3760:2022 for construction. Understanding these rules underpins every inspection and guides competent person qualifications.

How Does AS/NZS 3760:2022 Define Test and Tag Requirements?

AS/NZS 3760:2022 sets out procedures for visual inspection, earth continuity, insulation resistance and functional testing of portable appliances. It specifies test intervals based on environment severity and appliance type. For example, a wet or dusty workplace triggers shorter inspection cycles—a definition that drives testing protocols across all sectors.

What Are the WHS Regulations 2012 Requirements for Workplace Electrical Safety in Adelaide?

The WHS Regulations 2012 mandate that all electrical equipment in a workplace be maintained in a safe condition and regularly inspected by a competent person. Employers must record inspection dates, results and any remedial actions. This rule ensures traceability of compliance records and enforces accountability for safety.

Work Health and Safety Regulations 2012 and Electrical Safety

The WHS Regulations 2012 mandate that all electrical equipment in a workplace be maintained in a safe condition and regularly inspected by a competent person, with records of inspections, results, and remedial actions kept. This ensures traceability of compliance records and enforces accountability for safety in Adelaide workplaces.

Who Is a Competent Person for Performing Test and Tag in Adelaide?

A competent person holds relevant qualifications in electrical safety, such as a Certificate IV in Electrical Testing, plus hands-on experience with portable appliance testing equipment. They understand AS/NZS 3760:2022 standards, WHS obligations and can interpret test results correctly—ensuring reliable inspections before moving to construction-site specifics under AS/NZS 3760:2022.

How Does AS/NZS 3760:2022 Apply to Construction Sites in Adelaide?

AS/NZS 3760:2022 covers the design, installation and verification of temporary electrical installations on construction sites. It prescribes regular inspection of power tools and other electrical equipment at three-month intervals. This standard enhances AS/NZS 3760:2022 by addressing the unique hazards encountered during building and demolition.

What Is the Test and Tag Process for Adelaide Businesses?

Portable appliance testing follows a structured three-phase procedure to guarantee safety and compliance from start to finish. Visual inspection, electrical testing and documentation work in tandem to deliver a clear safety verdict on every item.

- Visual Inspection Technicians examine cords, plugs and casings for wear, cracks or overheating marks.

- Electrical Testing A portable appliance tester checks earth continuity, insulation resistance and polarity.

- Tagging and Reporting Each appliance receives a durable safety tag with the test date, result and next due date, plus a detailed compliance report is issued.

This sequence ensures visible faults are caught first, technical measurements follow and full records back up every safety decision.

What Does Visual Inspection of Portable Appliances Involve?

Visual inspection involves checking flexible leads for cuts, inspecting plug pins for corrosion and examining appliance housings for dents or burn marks. This step often reveals damage that can cause earth leakage or short-circuits. Identifying these issues before testing prevents equipment damage and informs subsequent electrical tests.

How Is Electrical Testing Conducted During Test and Tag?

During electrical testing, an appliance tester applies a low voltage to measure insulation resistance and earth continuity, followed by polarity checks. Failures at this stage—such as high leakage current—indicate immediate removal from service, ensuring only fully compliant appliances remain operational and paving the way for accurate record-keeping.

What Information Is Recorded and Reported After Test and Tag?

After testing, technicians log appliance details (make, model, serial), test results, corrective actions and the date for the next inspection. A comprehensive report enables businesses to track compliance status over time and demonstrates due diligence to insurers and regulators.

How Do Test and Tag Services Benefit Adelaide Industries?

Regular appliance testing goes beyond ticking boxes—it actively protects people, assets and reputations across Adelaide’s business landscape. Enhanced safety, legal certainty and cost control form the cornerstone of these services.

- Safety Assurance: Early fault detection reduces electric-shock incidents and fire risks.

- Legal Compliance: Adhering to AS/NZS 3760:2022 standards and WHS laws safeguards businesses from fines and insurance claims.

- Operational Continuity: Scheduled inspections prevent unexpected equipment failures and downtime.

These advantages reinforce a safer working environment, highlighting why test and tag is indispensable for risk management.

How Does Test and Tag Ensure Workplace Electrical Safety?

By systematically validating earth connections and insulation, test and tag prevents electric shock and overheating. This proactive approach cultivates a culture of safety, where every appliance is certified fit for use and hazards are eliminated before they escalate.

What Are the Compliance Benefits Under South Australian Law?

Maintaining up-to-date test and tag records demonstrates legal compliance with WHS Regulations 2012 and standards bodies. In the event of an incident, documented inspections prove that due diligence was exercised, reducing liability and supporting insurance claims.

How Can Regular Test and Tag Minimise Business Downtime and Costs?

Predictive testing identifies wear patterns and potential failures in advance, allowing planned maintenance during low-impact periods. This foresight avoids emergency repairs, extends appliance lifespan and spreads cost over scheduled intervals rather than incurring sudden high-repair bills.

How Can Adelaide Businesses Choose the Right Test and Tag Provider?

Selecting a provider with proven expertise, local insight and comprehensive services ensures accurate, efficient and compliant inspections. Evaluating credentials, regional knowledge and service scope guides businesses to the best fit.

- Qualifications and Certifications: Look for electricians with Certificate IV in Electrical Testing or equivalent.

- Local Knowledge: Providers well-versed in Adelaide’s WHS legislation and industry-specific hazards deliver tailored compliance.

- Comprehensive Services: Choose technicians offering RCD testing, emergency light inspections and detailed reporting.

What Qualifications and Certifications Should a Test and Tag Technician Have?

A competent technician holds formal training in portable appliance testing, knowledge of AS/NZS 3760:2022, plus liability insurance and ongoing professional development. These credentials affirm technical competence and commitment to safety standards.

Why Is Local Knowledge Important for Test and Tag Services in Adelaide?

Regional familiarity ensures providers understand site conditions—from coastal corrosion risks to manufacturing dust challenges—and know how South Australian regulators interpret WHS requirements, delivering practical compliance solutions that align with local norms.

What Services Should a Comprehensive Test and Tag Provider Offer?

Beyond basic appliance testing, top providers include RCD verification, exit/emergency light testing and thermal imaging for switchboards. Bundled services streamline compliance and reduce coordination efforts, giving businesses a single point of contact for all electrical safety needs.

What Are the Typical Costs and Frequencies of Test and Tag for Adelaide Industries?

Pricing for test and tag varies with sector complexity, appliance numbers and testing intervals. Test and tag rates in Adelaide typically range from $3.00 to $9.50 per item.

How Often Should Businesses Schedule Test and Tag to Stay Compliant?

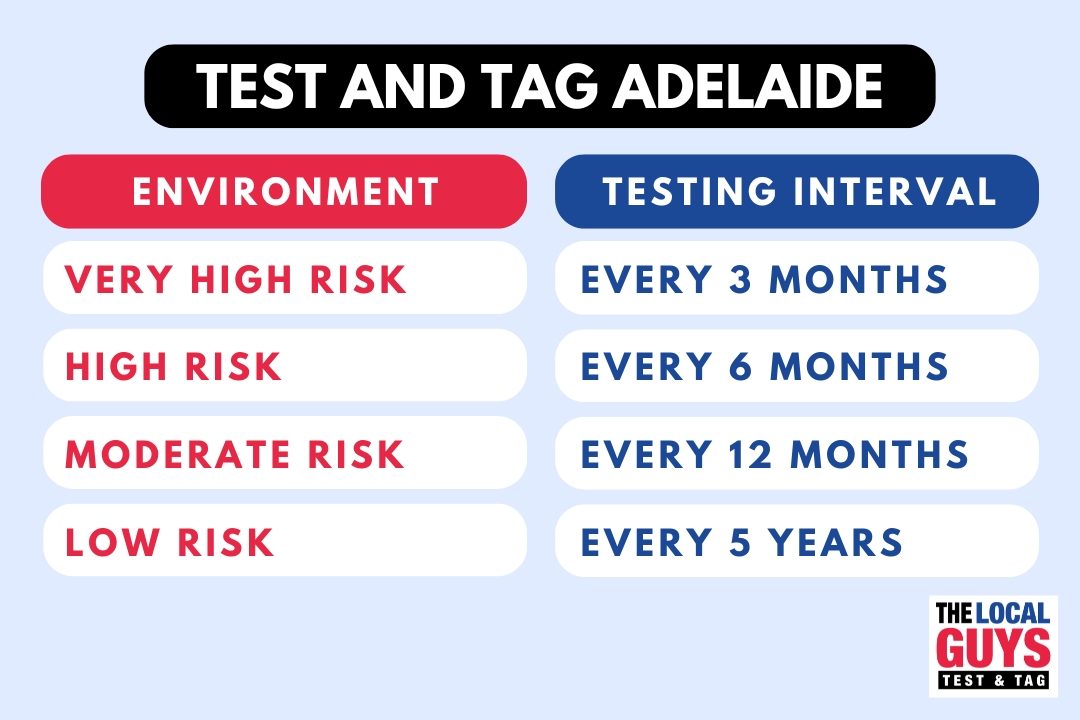

Scheduling follows environmental risk and appliance type: high-risk sites every three to six months, moderate-risk every 12 months and low-risk environments every one to five years. Mapping intervals to asset registers ensures legal adherence and uninterrupted workflows.

What Are the Penalties for Non-Compliance with Test and Tag Regulations in South Australia?

Failure to maintain test and tag records can lead to WHS infringement notices, fines up to tens of thousands of dollars and increased insurance premiums. In serious incidents, legal action and reputational damage can far exceed the cost of proactive inspections.

What Are the Frequently Asked Questions About Test and Tag for Adelaide Industries?

The questions below address core concerns around legal requirements, provider qualifications and equipment scope to clarify compliance expectations in Adelaide workplaces.

Is Test and Tag a Legal Requirement in South Australia?

Yes, the WHS Regulations 2012 require that all in-service portable electrical equipment in workplaces undergo regular safety inspections according to AS/NZS 3760:2022 intervals, making test and tag a statutory obligation.

Who Can Perform Test and Tag Services in Adelaide?

Only a competent person—an electrician or technician qualified in AS/NZS 3760:2022 testing methods, holding relevant certification and insurance—is authorised to conduct test and tag inspections and issue compliance tags.

What Equipment Requires Test and Tag in Adelaide Workplaces?

Any flexible-cord-connected or plug-in appliance, such as power tools, extension cords, office electronics and kitchen equipment, falls under portable appliance testing and must be inspected per the prescribed frequency.

How Does Test and Tag Relate to Workplace Health and Safety Compliance?

Test and tag forms a key element of electrical safety management under WHS legislation, providing documented evidence that businesses have maintained equipment in a safe condition and managed electrical risks proactively.

Every Adelaide industry covered here faces unique electrical safety challenges, but consistent test and tag practices unify compliance, protect people and secure business continuity. By understanding sector-specific frequencies, standards, processes and benefits, organisations can select qualified providers, budget accurately and uphold the highest safety standards. Investing in routine appliance testing today safeguards operations, reduces liability and fosters a culture of electrical safety across South Australia.

Book a Service Today

Don't put your workers or property at risk! If you want to stay up to date with fire and electrical safety testing, then contact The Local Guys! Our Test & Tag technicians help clients from the Adelaide CBD to regional South Australia stay safe and compliant. Whether it's PAT Testing, RCD Testing, or Fire Extinguisher Testing , locals count on our team for reliable and affordable services. Get a free quote from our friendly team now!