Portable Appliance Testing in Perth ensures that electrical equipment undergoes regular inspection, electrical testing, and labelling to prevent shocks, fires, and non-compliance fines. This article explains Western Australia's legal framework for Test and Tag, outlines frequency requirements by environment, describes the complete PAT process, highlights business benefits, identifies which appliances need tagging, guides you to choose a reliable provider, benchmarks typical costs, and addresses common concerns. By following these guidelines, Perth workplaces can uphold safety, meet duty-of-care obligations, and optimise equipment longevity.

What Are the WA Test and Tag Regulations for Portable Appliance Testing?

WA Test and Tag regulations require employers to conduct in-service safety inspections and electrical tests on portable appliances to verify earth continuity, insulation resistance, and operational integrity, thereby reducing electrical hazards and supporting legal compliance.

Which Laws Govern Portable Appliance Testing in Western Australia?

Work Health and Safety Act 2020 (WA)

The Work Health and Safety Act 2020 (WA) mandates that all electrical equipment in workplaces be maintained in a safe condition to protect employees from injury. Under this Act, employers have a duty of care to implement a testing regime, appoint competent persons, and keep records of inspections. This Act forms the legal basis for Test and Tag requirements in Western Australia, establishing the employer's responsibility for electrical safety.

Occupational Safety and Health Regulations 1996

The Occupational Safety and Health Regulations 1996, under the Work Health and Safety Act 2020 (WA), require employers to conduct in-service safety inspections and electrical tests on portable appliances. These tests verify earth continuity, insulation resistance, and operational integrity. These regulations provide the specific requirements for implementing a Test and Tag program to ensure workplace safety.

What Are the Key Australian Standards for PAT in WA?

AS/NZS 3760:2022 establishes the technical requirements for in-service inspection, testing, and tagging of electrical appliances in WA. These standards specify test procedures—earth continuity, polarity, insulation resistance, and functional checks—and outline tagging intervals to ensure ongoing electrical safety and regulatory conformity.

AS/NZS 3760:2022

AS/NZS 3760:2022 establishes the technical requirements for in-service inspection, testing, and tagging of electrical appliances in WA. This standard specifies test procedures and outlines tagging intervals to ensure ongoing electrical safety and regulatory conformity. This standard provides the detailed guidelines for the Test and Tag process, including testing procedures and frequency requirements.

Who Is Considered a Competent Person for Test and Tag in WA?

A competent person for Test and Tag in WA holds either a licensed electrician qualification or has completed a Nationally Recognised Course at a Registered Training Organisation (RTO). This training equips individuals with the skills to identify electrical faults, perform accurate tests, and apply compliant labels, ensuring reliable hazard detection.

Competent Person for Test and Tag in WA

A competent person for Test and Tag in WA holds either a licensed electrician qualification or has completed a Nationally Recognised Course at a Registered Training Organisation (RTO). This training equips individuals with the skills to identify electrical faults, perform accurate tests, and apply compliant labels. This clarifies the qualifications required to legally perform Test and Tag services in Western Australia.

What Are the Penalties for Non-Compliance with WA Test and Tag Requirements?

Work Health and Safety Act 2020: Penalties for Non-Compliance

Non-compliance with WA Test and Tag requirements can attract significant financial and legal consequences. Corporations may face fines up to AUD 300,000, and individuals responsible for safety breaches risk fines exceeding AUD 60,000 and potential prosecution. This highlights the serious legal and financial repercussions of failing to comply with Test and Tag regulations.

Failing to tag defective equipment can result in workplace incidents, reputational damage, and increased liability exposure.

How Often Should Test and Tag Be Performed in Perth Workplaces?

Testing frequency depends on the environment’s risk level and usage intensity to maintain safe electrical operation, prevent breakdowns, and comply with AS/NZS 3760:2022 requirements in WA.

Portable appliances in harsher settings require more frequent examinations, while those in low-abuse areas can extend intervals, optimising maintenance resources without compromising safety.

| Environment | Testing Interval | Rationale |

|---|---|---|

| Construction & Mining Sites | Every 3 months | High-risk conditions and heavy equipment use accelerate wear and damage. |

| Factories & Warehouses | Every 6 months | Moderate mechanical stress and dust exposure increase electrical fault potential. |

| Offices & Retail Spaces | Every 12 months | Regular usage with lower mechanical strain still demands annual safety verification. |

| Low-Risk Settings | Up to 5 years | Controlled environments with minimal handling reduce the likelihood of faults. |

Each interval aligns with risk profiles to ensure testing remains effective and resources are well allocated.

What Are the Testing Intervals for Construction and Mining Sites?

In Perth construction and mining environments, Test and Tag must be performed every three months to detect insulation breakdown, cord damage, and earth faults promptly under intense operating conditions.

How Frequently Should Factories and Warehouses Conduct PAT?

Equipment in factories and warehouses undergoes biannual testing—every six months—to address moderate abrasion, vibration, and exposure that can compromise electrical integrity.

What Are the Recommended Testing Frequencies for Office and Low-Risk Environments?

Office appliances and retail equipment are tagged annually, while devices in low-abuse settings such as laboratories and server rooms may extend inspection intervals up to five years, provided no visible damage arises.

How Does Environment Risk Affect Test and Tag Frequency?

Higher risk environments with moisture, dust, or mechanical impact demand shorter testing cycles, whereas controlled, low-traffic areas allow longer intervals, balancing safety assurance and operational efficiency.

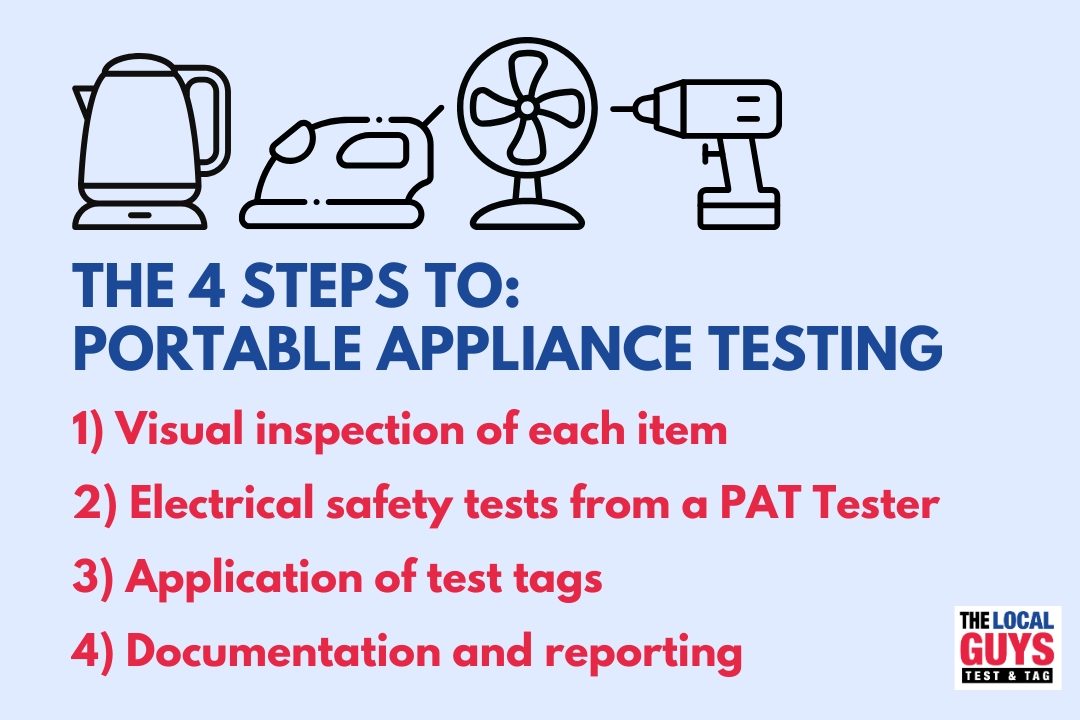

What Is the Step-by-Step Process of Portable Appliance Testing in Perth?

The PAT testing process in Perth comprises a visual inspection, a series of electrical tests, labelling, and documentation, ensuring every step confirms appliance safety, compliance, and traceability for audits.

- Visual Inspection to identify damage to cords, plugs, and casings.

- Earth Continuity Test to confirm proper grounding paths.

- Insulation Resistance Test to measure breakdown voltage thresholds.

- Polarity and Functional Tests to verify correct wiring and operation.

- Tagging with date, tester ID, and next due date.

- Record-Keeping in digital or hard-copy registers.

This systematic approach minimises the risk of untested appliances causing harm and provides a clear audit trail for compliance checks.

How Is Visual Inspection Conducted During Test and Tag?

The tester examines plugs, leads, and appliance bodies for cuts, frays, scorch marks, or loose connections, removing any unit showing visible hazards from service to prevent electrical incidents before testing proceeds.

What Electrical Tests Are Performed on Appliances?

PAT involves several diagnostic checks:

| Test Type | What It Checks | Benefit |

|---|---|---|

| Earth Continuity | Integrity of protective earth path | Prevents electric shock by ensuring grounding |

| Insulation Resistance | Resistance between live conductors and earth | Detects insulation breakdown early |

| Polarity | Correct wiring connections | Avoids reverse polarity hazards |

| Leakage Current | Current stray to earth | Identifies hidden faults before failure |

How Are Appliances Tagged and Documented After Testing?

After passing tests, each appliance is fitted with a durable label indicating the test date, unique ID, next test due date, and tester name. Records are entered into a register—often digital—facilitating quick retrieval during audits.

Why Is Digital Documentation Important for WA Workplaces?

Digital records enhance audit readiness, enable automated reminders for retesting, and allow analysis of fault trends over time, supporting proactive maintenance and demonstrating compliance to regulators.

What Are the Benefits of Professional PAT Testing for WA Businesses?

Professional PAT testing delivers enhanced safety, legal compliance, cost savings, equipment longevity, and potential insurance advantages by systematically preventing electrical failures.

Certified testers apply proven methodologies, reducing downtime and liability while reinforcing an employer’s duty of care obligations under WA law.

How Does PAT Enhance Workplace Electrical Safety?

Regular PAT prevents electric shocks and fires by detecting insulation faults and earth path failures early, ensuring all portable appliances operate within safe electrical parameters.

What Cost Savings Can Result from Regular Test and Tag?

- Extended equipment lifespan through preventive maintenance reduces replacement expenses.

- Fewer unplanned breakdowns decrease downtime costs and production losses.

- Avoidance of non-compliance fines preserves operating budgets and reputation.

These savings offset testing fees and contribute to healthier long-term asset management.

How Does PAT Support Legal Compliance and Duty of Care?

Adhering to Work Health and Safety Act 2020 and AS/NZS 3760:2022 demonstrates proactive risk management, fulfills statutory obligations, and positions employers favourably during regulatory inspections.

Can PAT Testing Improve Insurance and Risk Management?

Insurers often reward businesses with robust electrical safety programs through lower premiums and enhanced coverage terms, reflecting reduced risk exposure from electrical faults.

Which Types of Electrical Equipment Require Test and Tag in Perth Workplaces?

Any portable, hand-held, or moveable appliance with a flexible cord or plug must undergo PAT in WA workplaces to mitigate hazard risks and comply with regulations.

| Equipment Category | Examples |

|---|---|

| Portable & Hand-Held | Drills, kettles, toasters |

| Moveable Appliances | Vacuums, microwaves |

| Extension Leads & RCDs | Power boards, safety switches |

What Portable and Hand-Held Appliances Need Testing?

Power tools, kitchen appliances, and chargers with plug-in leads must be examined for wear, tested electrically, and tagged before use in any workplace.

Which Moveable Appliances Are Included in PAT?

Items such as vacuum cleaners, microwaves, and photocopiers—devices that can be repositioned and bear cords—require periodic PAT to confirm safety.

Are Extension Cords and RCDs Subject to Testing?

Yes, extension leads and portable residual current devices are tested for continuity, polarity, and leakage, ensuring protective mechanisms function correctly under load.

How Are Different Equipment Categories Tested and Tagged?

Testing protocols adapt to category: hand-held tools focus on insulation and polarity, RCDs undergo trip time tests, while moveable appliances include functional checks—all culminating in a compliant tag.

How Do You Choose a Reliable Test and Tag Provider in Perth?

Selecting a provider with accredited testers, calibrated equipment, and robust reporting ensures accurate, compliant PAT services that protect people and assets.

Evaluate providers on qualifications, on-site flexibility, record management capabilities, and transparent communication to secure a service aligned with WA regulations.

What Qualifications and Accreditations Should Providers Have?

Look for technicians who hold a Registered Training Organisation (RTO) certificate in PAT, licensed electrician credentials, and membership with relevant industry bodies, guaranteeing competence and current knowledge.

Why Is Experience and Equipment Calibration Important?

Providers with years of local experience understand WA’s unique safety environment, while regularly calibrated testers ensure measurement accuracy and compliance with AS/NZS 3760 specifications.

How Does Comprehensive Reporting Benefit Your Business?

Detailed digital reports with pass/fail data, date stamps, and historical comparisons support regulatory audits, simplify asset management, and enable trend analysis for proactive maintenance planning.

What Questions Should You Ask Before Hiring a PAT Service?

- “Can you demonstrate your tester calibration records?”

- “How do you schedule and remind us of retests?”

- “Do you provide digital access to test registers?”

- “What is your process for failed appliance remediation?”

What Are the Typical Costs of Portable Appliance Testing in Perth?

PAT pricing varies based on volume, access complexity, and equipment mix, offering models that suit one-off audits or ongoing maintenance programs.

Transparent quotes help businesses budget effectively and compare service value against compliance and safety benefits.

How Is PAT Pricing Structured: Per Tag vs. Minimum Charges?

Providers often offer per-tag rates for large volumes and minimum call-out fees for small jobs, balancing affordability with service viability for varying business sizes.

What Factors Influence the Cost of Test and Tag Services?

- Number and type of appliances

- Site accessibility and travel distances

- Frequency of retesting required

- RCD testing and risk assessment inclusions

Greater appliance diversity or remote locations can raise overall fees.

How Can Businesses Maximise Value from PAT Testing?

Consolidate testing into single visits, maintain clear appliance registers, and remedy failures promptly to reduce retest time and benefit from bulk pricing discounts.

Are There Additional Costs for RCD Testing or Risk Assessments?

Some services include RCD trip-time tests and on-site risk assessments as standard, while others list them separately; clarify inclusions upfront to avoid unexpected charges.

What Are Common FAQs About Portable Appliance Testing in Perth?

Perth businesses often ask whether PAT is legally mandatory, who can perform testing, how frequently it must be done, what consequences arise from non-compliance, and how Test and Tag prevents electrical hazards. Legally, WA law requires employers to maintain safe electrical equipment through regular inspection and testing by competent persons. Certified technicians conduct tests according to AS/NZS standards at intervals based on workplace risk profiles. Non-compliance can lead to substantial fines and increased liability, while proactive PAT reduces shock and fire risks, extends appliance life, and supports insurance coverage.

Regular, documented PAT not only meets statutory obligations but also fosters a culture of safety and accountability in WA workplaces.

Employers should engage accredited providers who offer clear scheduling, calibrated equipment, and digital reporting, ensuring seamless compliance and comprehensive protection against electrical hazards.

Through consistent adherence to WA’s Test and Tag regulations, Perth businesses safeguard personnel, assets, and reputation while optimising operational continuity.

Safe electrical practices beginning with Portable Appliance Testing form the foundation of a robust workplace safety system in Western Australia.

By partnering with qualified PAT professionals, organisations demonstrate commitment to duty of care, minimise risk exposure, and reinforce stakeholder confidence in their health and safety standards.

With thorough planning and regular maintenance, Test and Tag becomes an integral component of equipment management, delivering peace of mind and measurable business benefits.

Effective PAT programmes in Perth translate into safer workplaces, stronger compliance records, and reduced total cost of ownership for electrical assets.

Routine Portable Appliance Testing in Perth is a strategic investment that safeguards employees, satisfies WA regulatory demands, and avoids costly legal penalties. By understanding the regulations, applying the correct testing frequencies, following a structured PAT process, and choosing experienced providers, businesses can significantly reduce electrical hazards. Comprehensive digital documentation and professional reporting enhance compliance proof and asset management, while proactive testing extends equipment service life and can improve insurance terms. Embracing a rigorous Test and Tag routine demonstrates a genuine commitment to workplace safety and positions Perth organisations as leaders in duty-of-care excellence.

Safeguard Your Workplace

Book professional Portable Appliance Testing in Perth with The Local Guys today. Our accredited testers provide fast, compliant, and reliable Test and Tag services that keep your team safe and your business audit-ready. Call us now for a free, no-obligation quote and enjoy peace of mind knowing your electrical safety is in expert hands.